Medical Device Automation & Assembly Services

Automation, Assembly, Verification, & Packaging

Robust & repeatable assembly, verification, and packaging processes are as critical to the success of product commercialization as it is to the success of the contract manufacturer. SMC’s expertise with manufacturing & scaled-up automated processes provides assurance that each device is made using a reliable and verified process. Our industry-differentiating automation teams implement innovative processes and ensure the necessary, then design and build automation cells or may partner with automation specialty companies. Whether your program needs are met utilizing manual, semi-automated, and/or fully-automated system(s), SMC’s in-house automation expertise is available at each of our global facilities.

Comprehensive Support for Clinical Trials and Commercialization

Your SMC team can help develop a plan with you to get your devices ready for clinical trials and at the same time build a plan for full scale-up to commercialization, and everything in between.

Assembly Services Include

- In-house automation expert knowledge

- In-line sub-assembly

- Manual bench-top assembly aids

- Drug handling for assembled combination products

- Fully automated work cells

- Test systems for 100% verification

- ISO Class 7 and 8 assembly clean rooms

- Skilled human-touch assembly

- No touch – High-speed fully automated assembly lines

In-house Automation

Because every program is different, we work with customers to determine an optimum plan given the project’s technical requirements, volume, cost and timeframe. The best approach is often a multi-phased approach; a semi-automated system may be appropriate as the device and acceptance criteria evolve through development with a more automated solution, or several, as the device matures. Allowing to produce quality devices at the most competitive cost at various volumes.

Low-Volume Device Solutions

SMC enhances manual assemblies by designing and building automation stations to complete critical assembly tasks and verify the completion of that task. Typical equipment used includes integrated vision systems, test or verification stations, adhesive dispense & cure, US & Laser welders, presses, label printers, etc. These stations would typically utilize manual component feeding with the required operations being automatic to ensure the highest quality with tight control.

High-Volume Device Solutions

SMC’s extensive knowledge of automated systems and processes benefits projects suited for high-speed automation systems. SMC works closely with established suppliers who specialize in the design and build of high-speed automation systems. Together, we plan for the best method of delivering each component to the assembly process regardless of whether the component comes directly from an SMC molding machine or a supplier of electronics or labels; and for the best method of assembly including verification testing throughout the assembly process and final packaging.

SMC’s Automated Manufacturing Systems Capabilities Include:

High Volume Device Solutions

- Expert knowledge of high-speed automation

- Established automation supply chain

- An internal automation team serving all SMC’s global locations

- In-house designing, machining, programming and system construction

- Development of custom assembly stations and custom test stations

- 100% device verification systems

- Lab-based “Proof of Concept” activities

- Scale-up processes from development through full production

- Adhesive dispensing and curing

- Ultrasonic & Laser Welding

- Induction and ultrasonic inserting

- Robotic assembly using SCARAs, cartesian, and 6-axis robots

- Automatic Part Feeding (flex, vibratory, centrifugal, magazine, slice, etc.)

- Vision inspections, measurements, and/or guidance

- Flow and Pressure Decay Testing

- Force, Torque, and/or Distance Monitoring

- Various Measurement Technologies (LVDT, Vision, Laser Scanning, etc.)

- Artwork Application – Laser Marking, Digital Printing, Dry-Offset, Labeling, Hot Stamping, etc.

- Label Printing (w/ Verification)

- Integration w/ Packaging Lines

- Remote Work Cell Monitoring & Access

Explore Case Studies, Articles and Other Resources

-

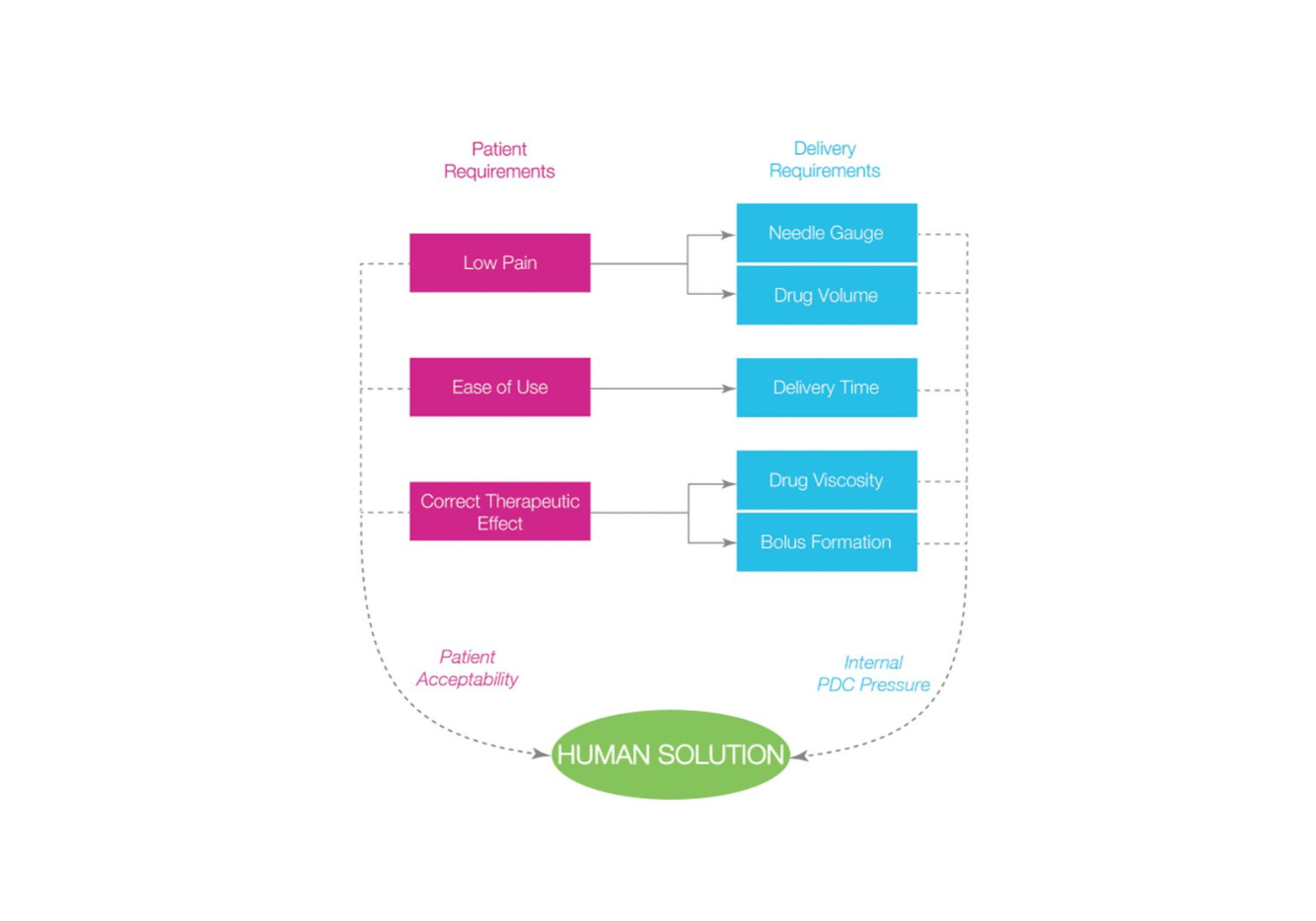

Combining Human Needs With High Viscosity Formulations

Within the injectable drug landscape, the availability and usage of high viscosity (HV) drugs is growing, often driven by developments such as long-acting injectable (LAI) technologies. Currently, these products provide significant advantages in terms of more convenient dosage volumes for patients and healthcare professionals (HCPs). With a trend towards self-administration, LAIs allow for less frequent…

-

Finding the Ideal Balance – “Where Risk and Cost of Quality Meet”

What is the answer to improve value for customers and reducing overall costs? Part of the answer resides within the functional activities of risk and cost of quality management. These critical processes are needed to reach and maintain the optimum operating space, and provide the value customers seek. Common challenges to effectively pull these two…

-

Insights Into Drug Delivery Device Manufacturing From Development Through Commercialization

With technology advancements and a greater understanding of effective treatment options, novel delivery methods are being introduced giving pharmaceutical companies a competitive edge and offering patients better solutions for their needs.